Asha Spring, Industrial Spring Manufacturers India

Established in 2000, Asha Spring & Engineering Co, Certified ISO 9001:2015 & CRISIL, is dedicated and experienced when it comes to springs, Industrial spring, Custom springs and metal stamping. Today Asha Spring & Engineering Co is privileged to be a multi-plant Industrial Spring Manufacturers India with a full range of products and services for springs and stampings manufacturers nationwide. We are a leading supplier to hundreds of internationally known original equipment manufacturers (OEM's). We are specialized for manufacturing of Compression spring, Torsion Spring, Coil Spring, Die Spring, Extension Spring, and Spiral Spring etc. All this spring are manufactured as per client drawing and specification.

Why Choose Industrial Spring Manufacturers India

Trustworthy Service

We work to serve you so that you can make your business stronger.

Dedicated Manager and Team

We assign a manager and a team to your project for better and perfect results.

Technical Proficiency

Our Team is highly proficient in the technology they use. They believe in understanding technology to a deeper level.

Customer Friendly

We listen to your problems with the utmost professionalism and friendly nature.

Timely Delivery

We give you knowledge about your project progress timely and communicate regarding the same.

Quality

The best delivered in time is our prime focus to increase satisfaction and trust. For us, time is the key !

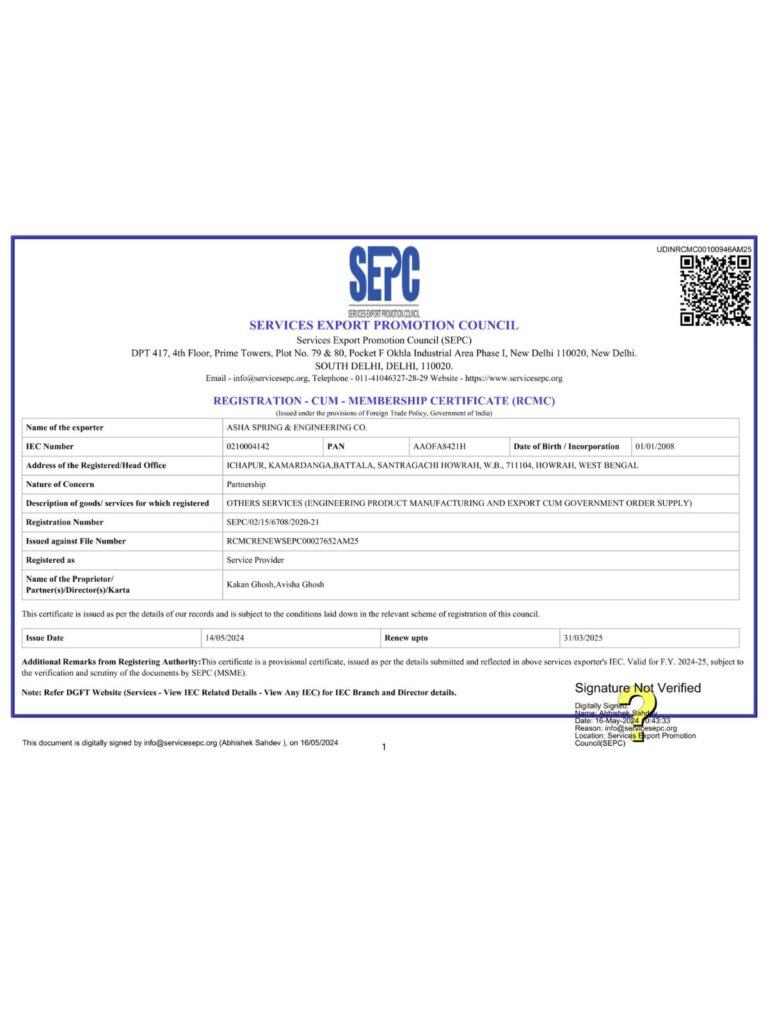

COMPANY CERTIFICATE

What We Offer

Top Industrial Spring Manufacturers India using top grades of wires and modern technology. In line with this, our products oozes excellence in terms of tolerance, high resisting force, geometrical symmetry, and optimal tensile strength. Our unwavering commitment towards manufacturing finest quality springs has catapult our reputation in the industry as the best compression springs supplier and producer. We give emphasize on acquiring complete customer satisfaction by virtue of avant-garde products, quality assertion and timely delivery of ordered springs.

Industrial Spring

Springs are an essential component in many industrial applications, ranging from automotive to aerospace. Springs are used for storing energy, absorbing shocks, and maintaining force or pressure.

Wire Springs

We are manufacturer & exporter of a wide range of products which include Wire Springs such as Wire Compression Springs, Custom Flat Wire Springs and Metal Wire Springs.

Die Springs

Empowering clients' production capability, we are a trustworthy manufacturer, supplier and exporter of Coil Spring. These are widely used in different applications such as garden tools, washing devices, chainsaw, industrial valves,

Railway Equipments

Our firm, ASCO Engineering & Enterprise, has remained nonpareil as a manufacturer, supplier and exporter of Railway Equipment. Some of the products offered under this range include Bogie Suspension Springs, Railway

Spiral Springs

Creating maximum client satisfaction, we are a highly reliable manufacturer, supplier and exporter of Spiral Spring. These find extensive usage in many application areas including generator, car safety belts, garden tools

Grid Springs

With the support of our high-ranking officials, we are able to provide Grid Springs, Grid Spring Resilient Coupling, Grid Spring Coupling, Grid Coupling, Industrial Grid Coupling Springs. We manufacture the couplings by making use